About Us

Discover Syndicate Knives, your destination for small-batch and one-of-a-kind artisan knives crafted in the heart of the Pacific Northwest. We pride ourselves on using only the finest steels and materials, meticulously overseeing each step of the production process in-house to uphold the highest standards of quality. Explore our website to learn more about our meticulous process, browse through a gallery showcasing our past creations, peruse our current selection of available knives for purchase, and don’t hesitate to reach out via our contact form for any inquiries or special requests.

Thank you for visiting Syndicate Knives, Made. For. Life.

Syndicate Knives

Artisan Handmade knives

Made. For. Life.

Handmade in the USA

Here’s the process:

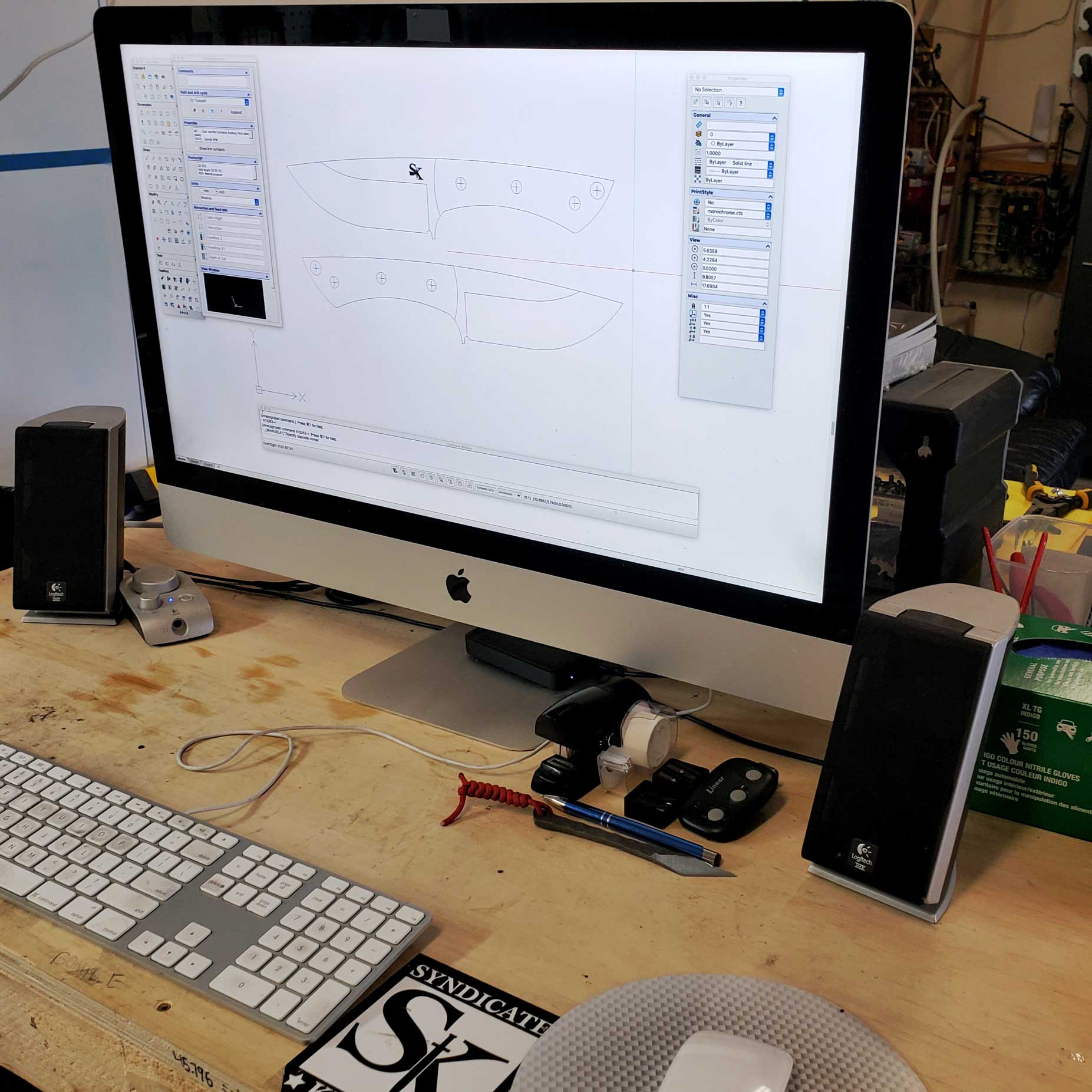

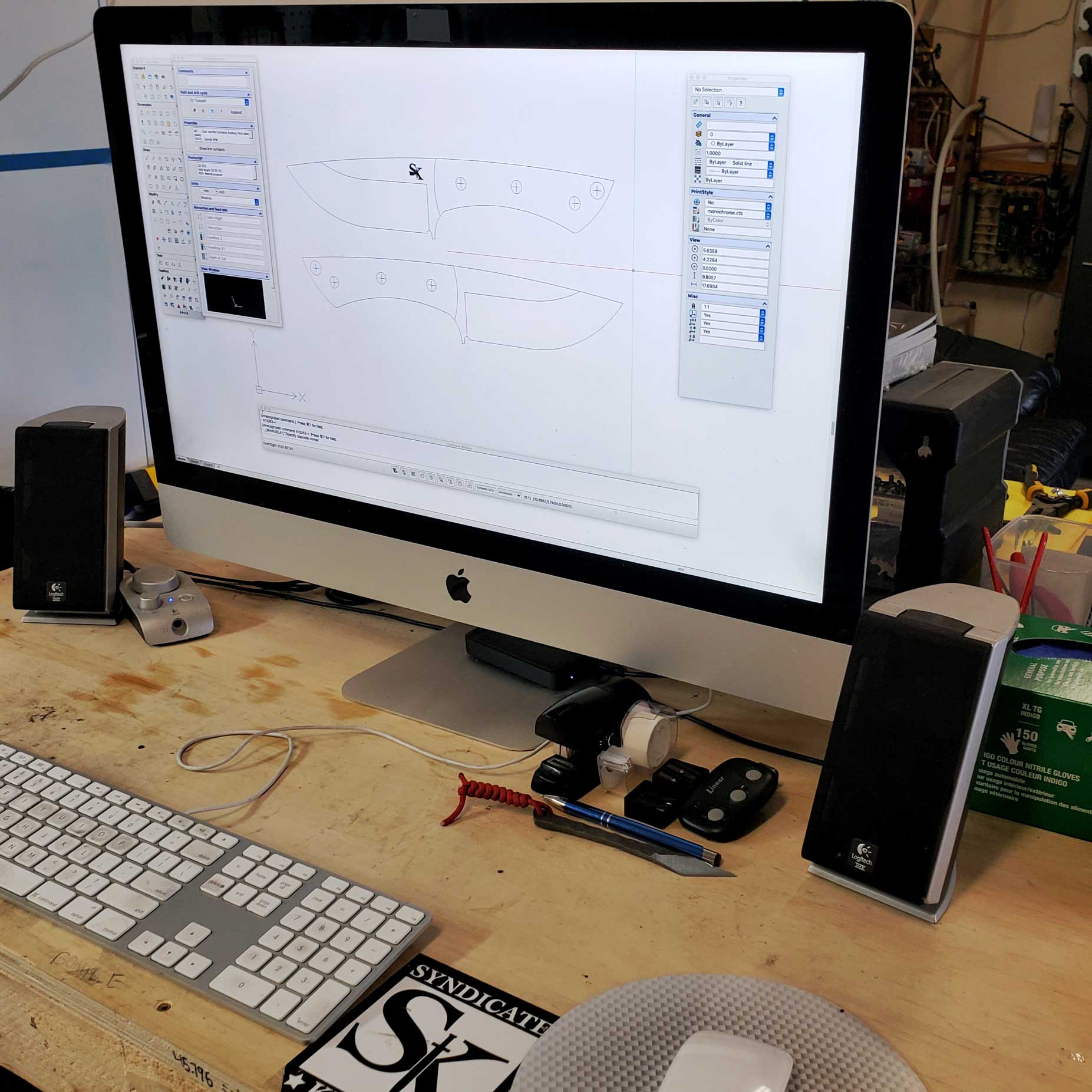

Computer Designed

Every design begins its journey in the digital realm, crafted using state-of-the-art modeling software. Once the design reaches its final form, it’s translated into a tangible prototype by utilizing advanced 3D printing technology. This step enables me to physically interact with the shape and functionality of each knife design, ensuring optimal performance and ergonomics before it’s transformed into steel.

Cutting the Shape

Depending on the knife, small batches are either cut with a water jet or by bandsaws in-house for custom orders. Utilizing a water jet ensures tighter tolerances, minimal material losses, and significant time savings compared to crafting custom one-off knives.

Flat and Smooth

Once the outline or profile is established, the next phase involves surface grinding the blade to attain a flat, smooth finish. This step is typically reiterated after heat treatment, depending on the desired final appearance.

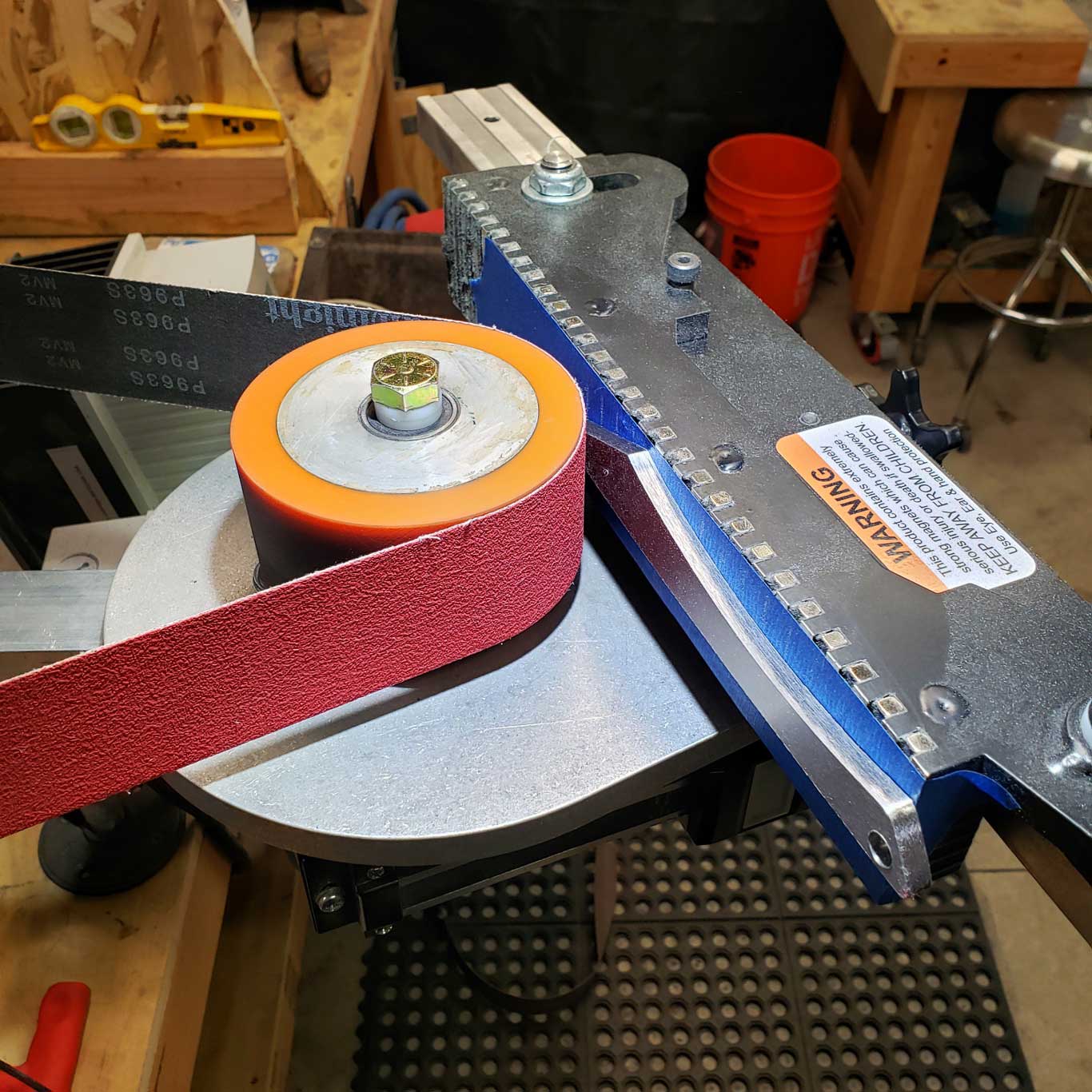

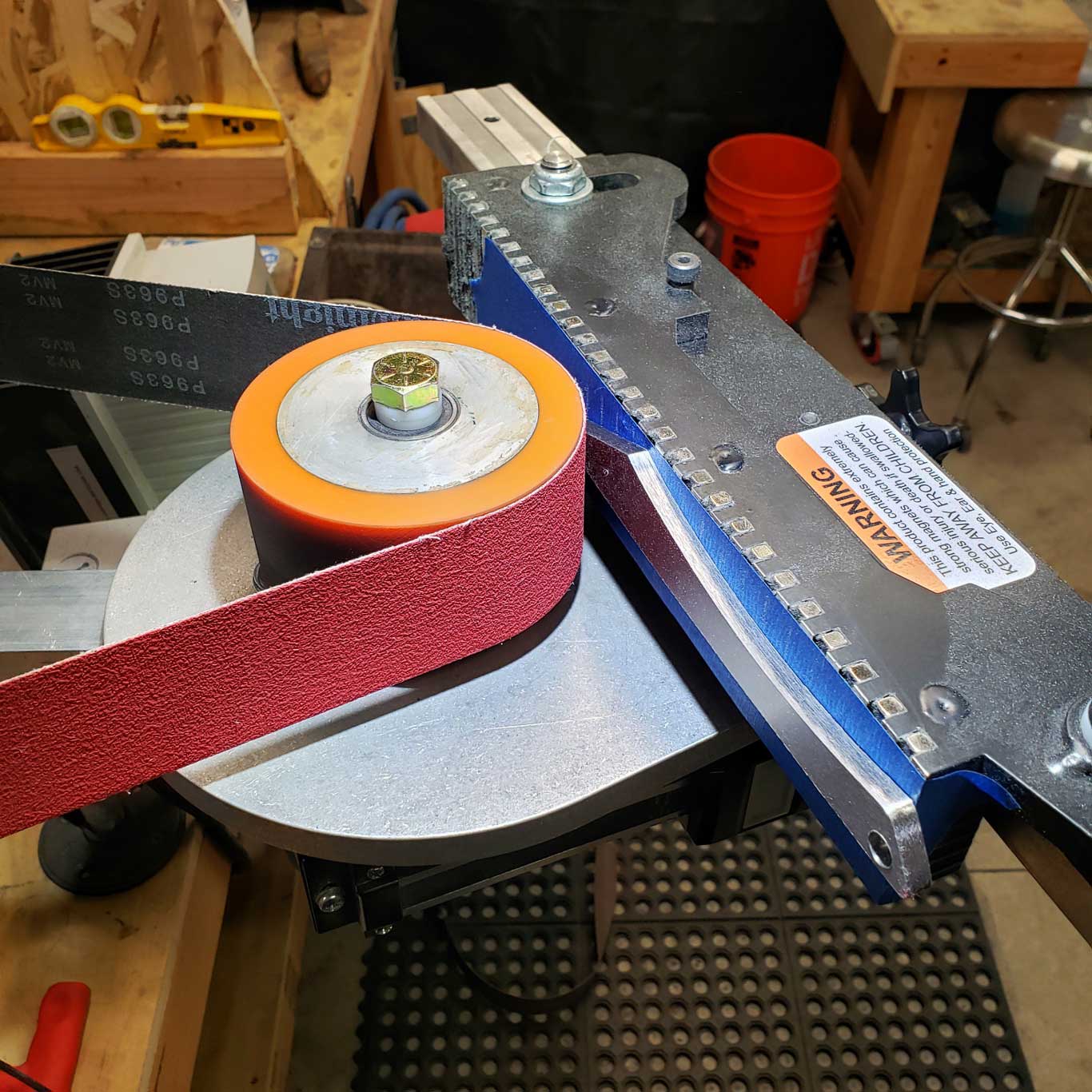

Main Bevels

With the blade now flat and profiled, it’s prepared for the primary grinding of the bevels. Various methods are employed for grinding in the bevels, contingent upon the blade style and design. The two common types are hollow and flat grinding. Hollow grinding utilizes a contact wheel, resulting in contoured grinds on the flats, while a standard flat platen yields a flat finish, as the name suggests.

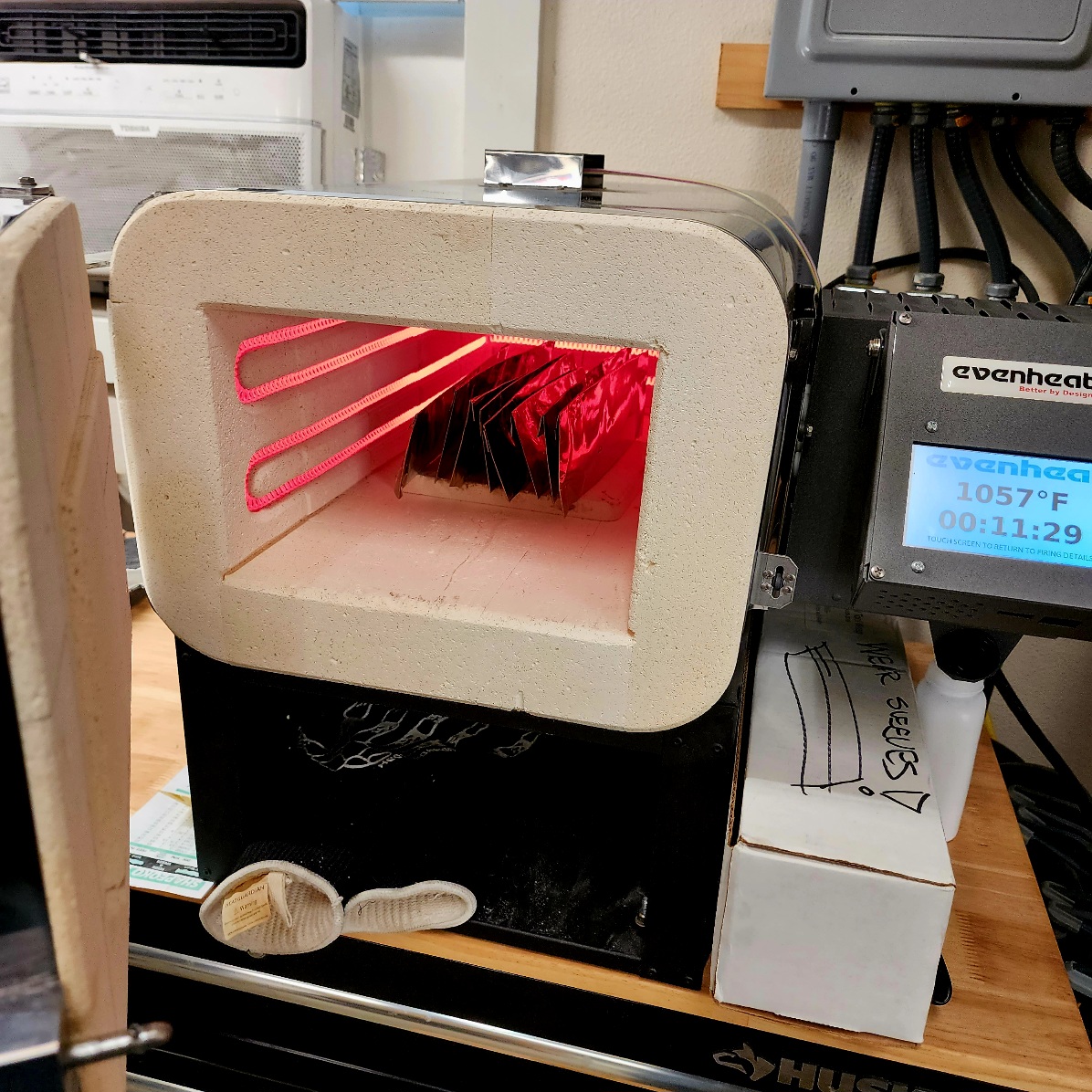

Heat Treating

The crucial step of heat-treating the blade involves subjecting it to specific temperatures, including cryogenic processes for certain steels ranging from 2200°F to as low as -200°F. While custom builds undergo heat treatment in-house, our main line of knives is entrusted to Buck Knives USA. Their state-of-the-art facility ensures guaranteed consistency in heat treatment, providing exceptional quality and performance.

Handle Shaping

Scales, known for their diverse materials, encompass both natural and synthetic handles, breathing vitality into a knife. A superior set of scales not only enhances aesthetics but also ensures ergonomic comfort. Every scale in our collection undergoes meticulous crafting, starting from 3D design to precision cutting and shaping by our in-house CNC Router.

Final step – blade finishing

Multiple finishing options await your custom knife: Stonewash involves submerging the knife in an acid solution before tumbling it in ceramic media. Cerakote, a Teflon finish baked onto the blade, safeguards against rust and contaminants. The remaining choices, satin and polished, undergo meticulous hand sanding and buffing to achieve their distinct finishes.

Laser Engraving

Our in-house 50-watt Fiber laser opens up boundless design possibilities. Each SK logo is meticulously “branded” etched onto every blade. Moreover, we have the capability to engrave names, dates, logos, or virtually anything that can fit onto the blade. Feel free to reach out to us, as the majority of engravings are included in our services at no additional charge.

Handmade in the USA

Here’s the process:

Computer Designed

Every design begins its journey in the digital realm, crafted using state-of-the-art modeling software. Once the design reaches its final form, it’s translated into a tangible prototype by utilizing advanced 3D printing technology. This step enables me to physically interact with the shape and functionality of each knife design, ensuring optimal performance and ergonomics before it’s transformed into steel.

Cutting the Shape

Depending on the knife, small batches are either cut with a water jet or by bandsaws in-house for custom orders. Utilizing a water jet ensures tighter tolerances, minimal material losses, and significant time savings compared to crafting custom one-off knives.

Flat and Smooth

Once the outline or profile is established, the next phase involves surface grinding the blade to attain a flat, smooth finish. This step is typically reiterated after heat treatment, depending on the desired final appearance.

Main Bevels

With the blade now flat and profiled, it’s prepared for the primary grinding of the bevels. Various methods are employed for grinding in the bevels, contingent upon the blade style and design. The two common types are hollow and flat grinding. Hollow grinding utilizes a contact wheel, resulting in contoured grinds on the flats, while a standard flat platen yields a flat finish, as the name suggests.

Heat-Treating

The crucial step of heat-treating the blade involves subjecting it to specific temperatures, including cryogenic processes for certain steels ranging from 2200°F to as low as -200°F. While custom builds undergo heat treatment in-house, our main line of knives is entrusted to Buck Knives USA. Their state-of-the-art facility ensures guaranteed consistency in heat treatment, providing exceptional quality and performance.

Handle Shaping

Scales, known for their diverse materials, encompass both natural and synthetic handles, breathing vitality into a knife. A superior set of scales not only enhances aesthetics but also ensures ergonomic comfort. Every scale in our collection undergoes meticulous crafting, starting from 3D design to precision cutting and shaping by our in-house CNC Router.

Final step – blade finishing

Multiple finishing options await your custom knife: Stonewash involves submerging the knife in an acid solution before tumbling it in ceramic media. Cerakote, a Teflon finish baked onto the blade, safeguards against rust and contaminants. The remaining choices, satin and polished, undergo meticulous hand sanding and buffing to achieve their distinct finishes.

Laser Engraving

Our in-house 50-watt Fiber laser opens up boundless design possibilities. Each SK logo is meticulously “branded” etched onto every blade. Moreover, we have the capability to engrave names, dates, logos, or virtually anything that can fit onto the blade. Feel free to reach out to us, as the majority of engravings are included in our services at no additional charge.

Handmade in the USA

INSTAGRAM GALLERY

Syndicate Knives

Artisan Handmade knives

Made. For. Life.

Etsy Store

Available Knives

Get In Touch

Battle Ground, WA USA

E-mail: info@syndicateknives.com